How a woman entrepreneur is changing the face of pallet industry

For those who saw Priya Prakash, managing director of Bengaluru-based startup Eco Pallet, carrying pallets to impress customers, she looked like “Lady Hercules.”

This is because these pallets, which are basically a packaging material, usually weigh at least 30 kg but the secret of carrying Prakash is that it barely weighs 4 kg. Eco Pallet, founded in 2015, has been selling these sustainable, lightweight pallets, which have environmental impact, economic impact, and social impact.

Priya Prakash, General Manager, Eco Pallet

In the short period of launching these pallets, mainly from waste wood previously used for packaging, Eco Pallet has around 40 clients including Mahindra Logistics, YCH Logistics and Wexford Laboratories. “Our pallets are going abroad and being reused there,” says the company’s managing director, a first-time entrepreneur whose company started its journey by purchasing a patent for a pallet made of Thermocol from a company in Hyderabad. “Priya (Prakash) is perhaps the only female entrepreneur in the pallet industry that is overwhelmingly male-centric. Not only is the top management but the sector in general including the factories and the people involved, dominated,” said Joseph Franklin, CEO of Eco Pallet. men hard.”

Once the founders of Eco Pallet bought the Hyderabad company’s patent, it was ‘love at first sight’. Although thermocol is light, if the right materials are added, it can become a pallet that can bear more weight and is also environmentally friendly. “When we started selling these products, the pharmaceutical industry welcomed them. But we were unable to scale them up because they only cater to a niche market,” Priya Prakash said.

“We haven’t really been able to drive it in FMCG or in sectors other than pharmaceuticals. Franklin said.

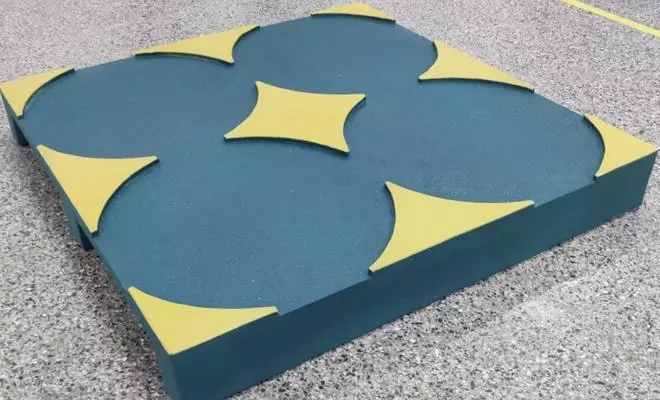

He said the pallets, which serve as a surface on which almost all raw materials and finished products are transported or stored in warehouses, are made of expanded polystyrene (EPS). Another high impact polystyrene material with EPS is used to make the pallets, which are molded.

A pallet usually weighs around 25kg and can hold 800kg to 1 ton, but our lightweight Eco Pallet product can bear the same weight. After the thermal pilot, Franklin said, Eco Pallets switched to wood pallets. “Instead of using new wood, we’ve used recycled wood that people throw away after they’ve been cut and made. We use that to make pallets and spray them with our patented chemicals that we’ve developed over the last three or four years.”

Joseph Franklin, CEO, Eco Pallet

The chemical, which is mainly polyurea, makes the pallet fire-retardant, waterproof, anti-fungal and anti-static, said Priya Prakash, adding that the carbon footprint was the biggest game-changer for the company’s pallets, which are of 3 types – plastic, wooden and EPS. “If you had to make a plank of wood, carbon dioxide (CO 2) approximately 25-26 kg. CO 2 Emissions for making a single shingle are anywhere between 40 and 70 kg. So, when we made off the pallet, our carbon emissions were only 30 grams. So, the environmental impact we are bringing to the table is massive,” said Priya Prakash.

Mahindra Logistics, which has taken on these platforms, said its emissions would be 18 percent lower. The shelf life of a wooden pallet is only 12-18 months. “We found that we can actually increase the life span to five years without any repair. We decided to look for scrap wood because we felt the pain that we had to cut down a tree to make a pallet,” said the manager of the company.

“We looked at scrap wood because its market is as big as that of timber. This world wondered when we did the same treatment. It increased its weight-bearing capacity and became compliant with international standards for phytosanitary measures. We also did a life-cycle assessment.”

continuous

Thus, the pallet has become a sustainable one with circular economy with no need to grow the better part of the tree but the scrap wood can be recovered. Eco Pallet manufactures its products from scratch at its unit in Dubalapura near Bengaluru in the state of Karnataka.

From the manufacturing unit, the pallets find their way to other parts of the country and the world. “Our pallets are lightweight and approved by agencies like the Indian Institute of Packaging. So it’s a one-way pallet that can go from here to another country and then it can be recycled there. It’s used and recycled and reused again,” she said.

In terms of trees, especially the pine wood that is used in the wooden pallets, it takes 19 years to plant one. You will be able to make 40 pallets, say 1200 mm in size, from one tree. “After 12-18 months, about 32 pallets entered the landfill and eight pallets were rescued,” Priya Prakash said.

By using scrap wood, there is no need to cut down a tree for pallets. In India, about 70 million pallets are used annually with timber coming from New Zealand or Uganda. Now it also comes from Australia or Canada, she said, as pine wood from Ukraine has ceased to be supplied. “Our platforms make transportation easy. It makes a huge difference in the weight of the goods, as the goods are charged on a per kilogram basis,” said Franklin.

“We are also cost-effective. Conventional pallets cost 2,000 rupees and then companies have to pay 200 rupees per year as annual maintenance cost. Each of our pallets costs 2,500 to 2,800 euros and we offer a seven-year warranty,” Priya Prakash said, adding that the product Tested on various standards including PFAs.

An anecdote was told where YCH bought a good number of the company’s pallets for three months and in the fourth month it stated that the pallets didn’t break and you wouldn’t need to buy more. “This is the amount of savings for the company and for the environment. Unfortunately, they will not need new pallets, but we are very happy to lose orders from these customers, ”said the general manager of the company.

When it started, the problem with Eco Pallet was that it found it difficult to get people, especially purchasing department employees, to understand the overall long-term savings. Including environmental benefits, said Priya Prakash. People today understand sustainability and the need to stop deforestation, she said, adding that the company would like to work with the government, especially the Food Corporation of India (FCI), in stockpiling food grains. “We want to change the way the current cap and base are stored and used on these platforms. We have also been invited by the governments in the United States and Finland. The UAE is another country to look at,” she said.

The use of pallets may stop moisture or water seepage from the bottom of the wood chips used by the FCI, into the jute bags in which the food grains are stored. “Once the government looks at our platforms, these problems can be resolved,” Priya Prakash said, adding that coffee is another area the company is looking into.